Tooling 101: Print Plates & Cutting Dies

Tooling [ too-ling ]

noun

work done with a tool or tools

Machinery

1. a number of tools, as in a particular factory

2. the planning and arrangement of tools for a particular manufacturing process

What is tooling?

Cutting dies and print plates used in point of purchase displays and retail ready packaging are referred to as tooling. They are custom made to fit each component for the project.

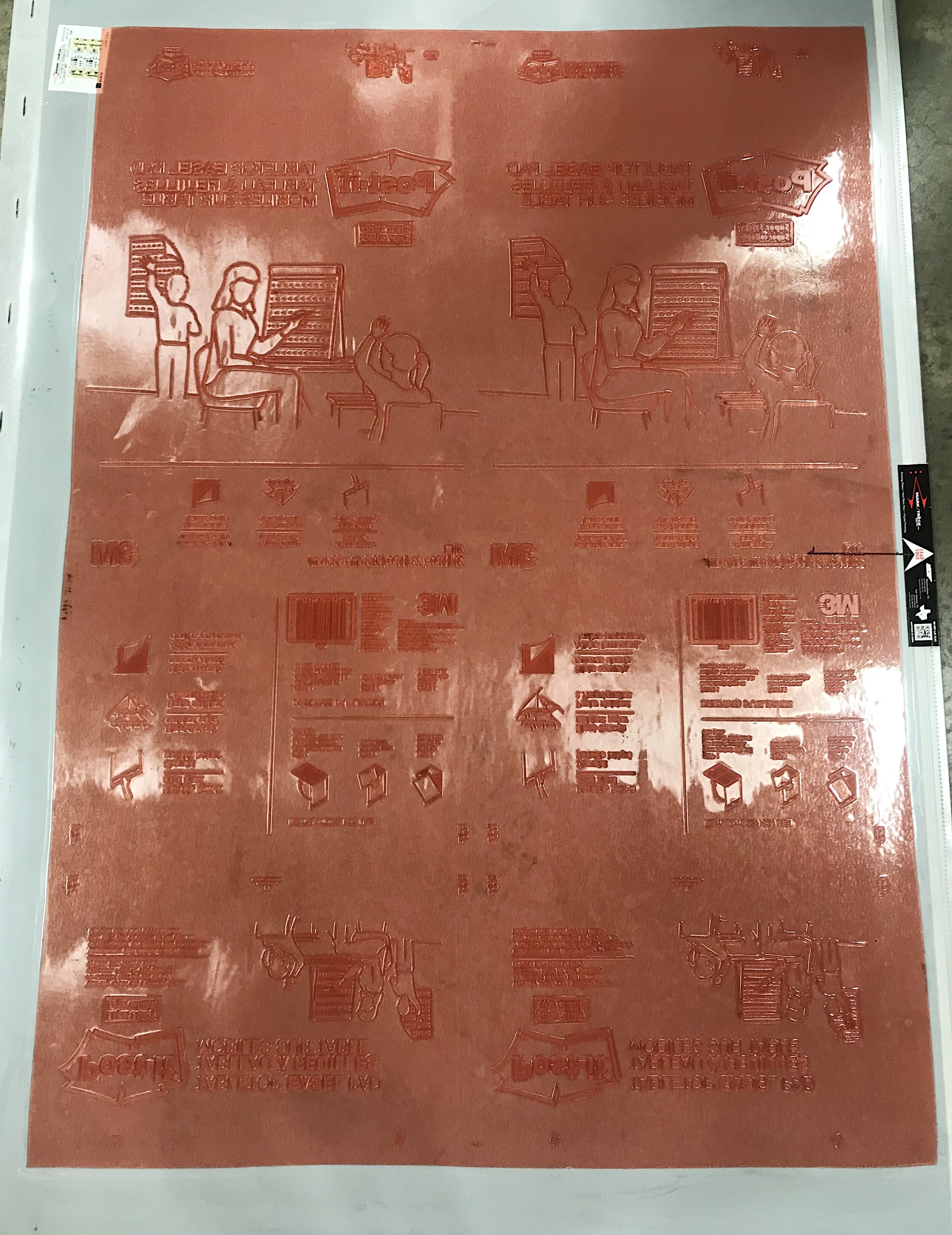

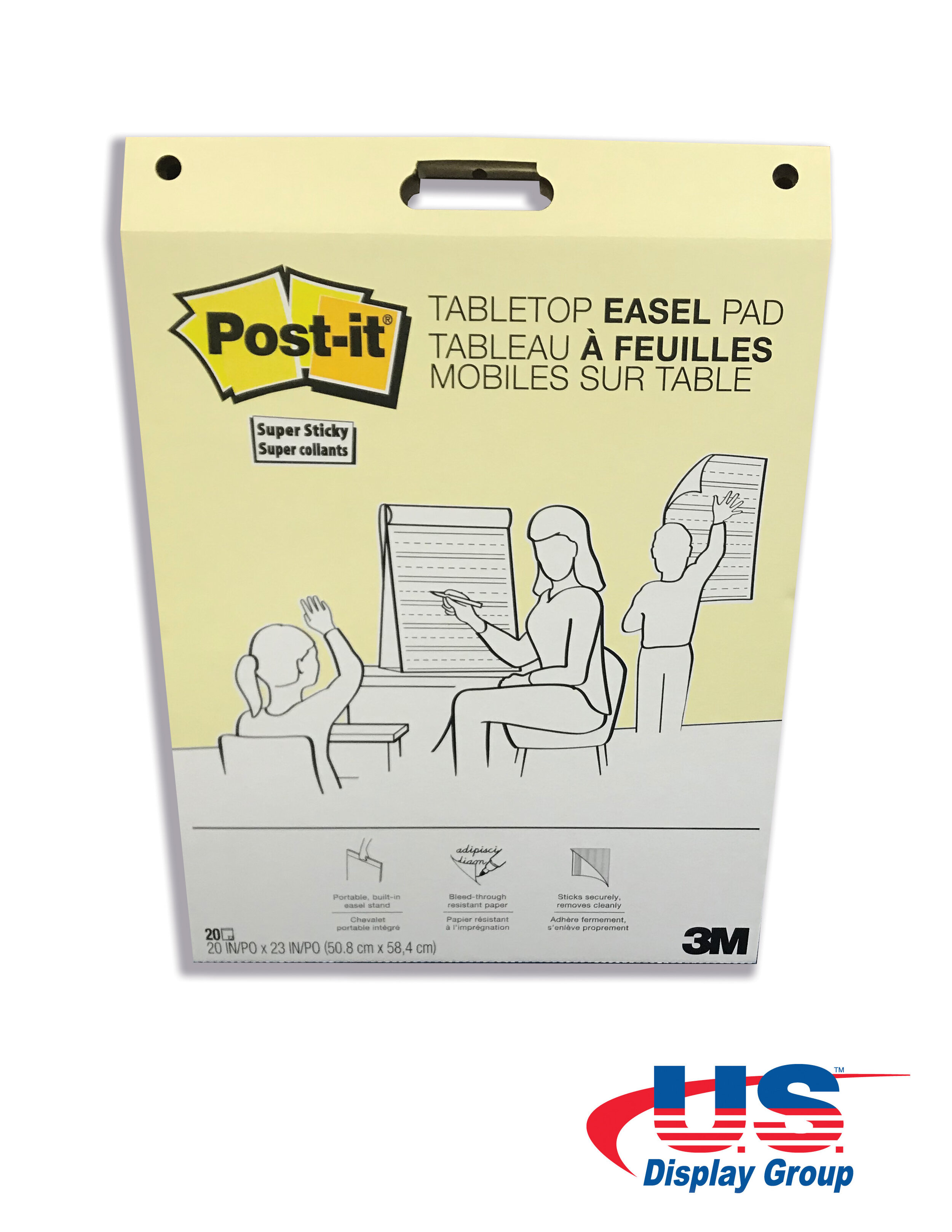

Print Plates

1. What is a print plate?

A print plate is used for flexo printing and is a large custom stamp made from a polymer material. It attaches to a machine cylinder to apply graphics on to the corrugated display component. A specific print plate is needed for each color you are printing on the display.

2. Are print plates always necessary?

Print plates are not necessary when a digital printer or litho is used to apply graphics to the component. Our Barberan Jetmaster 1750 digital printer prints directly to the corrugated sheet and does not require print plates.

3. Can a print plate easily be changed?

The formed polymer print plate is made custom for every component. Changing your design once the print plate is manufactured isn’t as easy as it may seem. Making a change typically requires making a completely new custom print plate. Any changes need to be reviewed by the print plate manufacturer.

4. How long do print plates last?

Print plates can be used over and over. The polymer plate can warp or degrade over time. However, multiple uses can be expected.

The print plate below shows that a separate print plate is needed for each color on a display.

Cutting Dies

1. What is a cutting die?

A cutting die is like a cookie cutter. It is made from wood (typically ash or birch), rubber, and steel rule. Steel rule is inserted into the wood and cuts the display components out of the corrugated material. Cutting dies are mounted to machinery to cut out components at a high rate of speed. It’s an efficient, effective way to get you the best desired product.

2. Are there different types of cutting dies?

Yes, there are two types of cutting dies: rotary and flat.

3. What's the difference between rotary and flat cutting dies?

Rotary dies are round and are typically utilized for high volume or large components. Steel rule insertion is slightly limited on the rounded shape so this style die is not used for intricate designs.

Flat dies can be used for various order volumes. A flat die offers options for machine manufacturing. Clam shell and Bobst utilize flat dies. Smaller run sizes of 500 or less will usually have a flat die.

If you have additional questions regarding cutting dies, print plates, and getting started with the display process, email us at info@usdisplaygroup.com!

Posted on Thu, June 27, 2019 by Whitney Scott